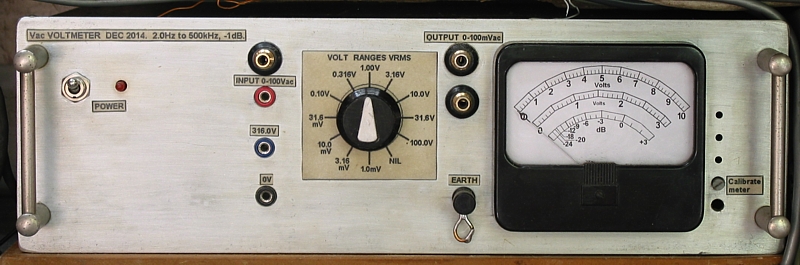

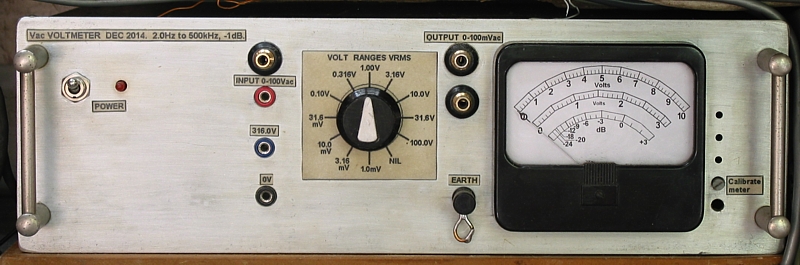

Vac meter 1, discrete solid

state. 2013.

Front panel, 2013.

This page is about the Vac meter I designed and built using an

old analog meter and

rotary wafer switches re-cycled from old test gear made in

1950s. There are 3 "op-amps"

which are built using discrete small size modern TO92 package

bjts and j-fets, plus

modern Si diodes, R and C.

The above front panel and the aluminium box behind was

previously used at ANU for a

meter to monitor vacuum hardness.

Images below include :-

Fig 1. Resistance divider.

SHEET 1. Block diagram for range switch, 3 amps and 1

meter.

Fig 2. Meter Dial.

SHEET 2. Range switch and Amp 1 details.

SHEET 3. Amp 2 details.

SHEET 4. Amp3 and meter details.

SHEET 5. Power supply.

Why build your own signal voltmeter?

It is very good training for the mind. What good are you if you

wish to make new electronic

gear without being able to build a good signal voltmeter which

works as well just as well

or better than products for sale costing hundreds of dollars?

What makes a good signal voltmeter?

Most voltmeters meters on the market are "digital" multi-meters,

DMM, and usually hand

held units powered by a small 9V battery.

They have numerous ranges and functions and readouts. All these

are very easy to use,

especially types with auto range selection,

like a Fluke 117, a good brand.

Advantages :-

1. Light weight and size.

2. Large number of functions, Vdc, Vac, Amps, continuity, peak

and hold,

diode and bjt properties, frequency, inductance, capacitance.

3. Resolution to 4 significant figures.

4. Able to be used in "floating" mode to measure across 2 live

circuit points.

Disadvantages :-

1. Fragile when used with tube circuits; likely to fail easily

from high voltages

applied at input, often higher than DMM the unit's maximum

ratings.

2. Over time, they slowly lose functions, and become impossible

to fix.

3. Cannot read Vac where a lot of Vdc exists.

4. Cannot read Vdc where a lot of Vac exists.

5. Take far too long to settle down to give a measurement.

6. No back lighting to LCD display.

7, Display has many range selections but text size is far too

small and decimal

points don't show prominently.

8. Bar meter is inadequate.

9. Cannot read Vac frequencies accurately below 7Hz or above

1kHz.

10. Have rather high input capacitance for Vac.

11. The 9Vdc batteries go flat too soon, maybe in 1 month with

constant use.

The first Fluke DMM I bought in 1993 gave most functions

for 20 years.

But the millivolt Vac range died, then resistance measurement

died, then Vac range

was erroneous, so it became useless junk for the re-cycle bin.

But it out-lasted about

4 other DMM I bought from Jaycar, of Digitech brand which was

the worst.

The 1993 Fluke had most of the advantages and few disadvantages.

My replacement Fluke 117 has a few more useful functions and is

acceptable.

But the next Fluke 117 I bought was not as good as the

1993 model it replaced.

When using Vac auto range the meter could not read 0.0Vac. The

lowest Vac was always

0.022Vac minimum displayed. When using the mV range for Vac, any

presence of Vdc

obliterates the measurement of Vac, so you must use a 0.01uF cap

in series with red

lead to measure low Vac where any Vdc was also present. But then

the readout of low

level Vac becomes slow, no better than the awful Digitechs etc.

And you cannot read

below 3mVac accurately. One must get used to a new item where

obvious shortcomings

are never described in manuals or data for the item. Fluke

manufacturing in USA was

transferred to China, and the quality seemed to nosedive.

After becoming fed up with the first Fluke 117 I bought,

I examined another in a store

which sold to electricians, and this one was OK, red right down

to 0.0Vac with the Vac

and mVac ranges, so I bought a second Fluke 117. I have retired

from trades these last

few years but the later Fluke remained OK. So there must have

been something wrong

with calibration of the first one, but I could not see anything

adjustable within the case.

To avoid 9V battery replacement I used 6

x 1.5 D-cell batteries soldered together in

series to make a single large long life 9Vdc battery. These are

then wrapped with

insulation tape between two sheets of thin plywood to make them

well insulated from

anything on the bench or in equipment. You could also explore

use of rechargeable

batteries. Such batteries lasted years.

Be VERY CAREFUL measuring any high

voltages!!!!!

It is always dangerous to work on tube circuits even when there

is only +/- 200Vdc pk.

All Vac above 100Vrms can be dangerous.

When working with transmitting tubes such as 845, 813, the anode

supply Vdc may

exceed +1,000V. These voltages are HIGH and LETHAL.

The high Vac and Vdc in vacuum tube gear can easily destroy

solid state test equipment.

All octal output tubes such as 6L6GC, EL34 or KT88 can have

combined anode peak

Vac and Vdc exceeding the 600V typical max input voltage allowed

for a DMM.

To minimize meter damage, always measure Vac at anodes

between anode and from

B+ input to OPT to avoid including high Vdc with the Vac being

measured.

Always monitor Vac at OPT sec with CRO.

So you always anticipate what you may expect at anodes or

OPT primary windings.

A single 845 making 24W into load of 12k0 generates 536Vrms, or

+/- 758Vpk,

and Vdc at anode with cathode biasing could be 1,250Vdc above

0V. Any DMM

could easily be fried to a crisp.

A PP amp with KT88 tetrodes may normally have B+ = 480Vdc, with

270Vrms at

each anode for 36W to RLa-a 8k0. But if there is no sec load

connected, and high

input signal, Va-a can become 4 times the 270Vrms due to energy

stored in leakage

inductance so that each anode can have Va pk = 2,000V above 0V.

You have been warned!

YOU must THINK before making any

measurement !!!!

You must know exactly what you are probing, and estimate what

could be the

highest voltage likely to be found. To work on tube gear you

really need to have

a couple of fixed resistance dividers on circuit boards in

plywood cases and fixed

on panels near the work area to allow meter leads to be

connected to low voltage

output from divider and probe leads then taken from high Volt

input for divider.

You may think a 10:1 reduction CRO probe is both sensible and

handy, but they

are no good for HV. Much better insulation is possible with a

fixed resistance

divider.

All test gear should have input protection preventing damage

when Vin exceeds

1,000V. Not all DMM have such a high max Vin rating. I once

accidentally applied

a pulse voltage over 2,000Vpk to a solid state LabTech CRO. The

repairs cost far

more than what I'd paid for it, and the complexity meant I could

only keep

replacing chips and bjts etc until it worked, and it never

regained all its functions.

It then developed more faults so it went out with the rubbish. I

repeatedly burned

the output bjts in a solid state function gene. This was due to

accidentally allowing

its output to be momentarily connected to something in a tube

amp at more than

100Vdc. I repaired it several times but I finally murdered it in

cloud of smoke and

bad smell after allowing its output to contact 240Vac mains for

2 seconds.

I had fitted protection but even that failed.

So I forced myself to learn good

workshop habits.

Do not clip meter leads between tube anodes and 0V. Try to avoid

using any leads

with alligator clips, especially non-insulated types because

sooner or later,

you will touch the wire on meter to a HV, and POOF. Do not allow

any ends of

leads to gear to lay unplugged on bench. If any lead from a

signal generator or

voltmeter is not being used, unplug the whole lead.

A stand alone cathode follower in a box can be a good buffer

between all signal

genies and amp inputs or outputs. This can be arranged to have

many megohms

of input Z and high bandwidth. It is also possible to make a

fully floating buffer unit

with mains supply also floating with well separated primary and

secondary mains

windings. The cathode follower output may drive a 10k:1k0

transformer with

insulation rating 4,000V, so that Vac readings across two active

circuit points at

different Vac and Vdc may be made, while the transformer sec

always remains at 0Vdc.

But iron cored transformers have limited Vac range and

bandwidth, and add some

distortion to Vac.

Use an RCA input socket when "bread-boarding" a new circuit so

stray contact to B+

or high Vac output is less likely. I often make sockets for 2mm

or 4mm probe leads

using say 6 turns of 1.2mm dia copper wire and soldered to the

0V rail on board.

So risk of the OOPS moment is dramatically reduced.

Most of the electrical shocks I had were from unguarded

mains input wiring.

Although the item is turned off, there are often live Active

terminals before the mains

switch and which have not been covered with protective

shrouding. Always place

covers preventing contact to live mains inputs.

For HV measurements without shock or wrecking meter, here are

details of a

resistance divider so that a possible 4,000V can be reduced to a

maximum of 400V.

Fig 1. Resistance divider.

The above resistance divider can be made using circuit board

inside a sheet

metal which MUST be connected to EARTH. A strongly made plastic

box could

also be used which does not need to be earthed.

The input leads to divider must have good insulation rated for

5,000V which may

possibly be purchased as spare input leads for the best of Vac

meters.

I show TWO Vac reduction ratios, 1 : 10 and 1 : 100. Both Vac

and Vdc can be

inputted, or Vac only if C1 is included. C1 = 15nF, and LF pole

with 10M0 Rin is

at 1.0Hz.

The exact reduction ratios will only exist where VR1 and VR2 are

adjusted to suit the

Rin of a Vac meter connected at output.

Consider use of Vac meter with Rin = 3M0 connected from output

to Com.

For 1 : 10 measurement, switch S1a+b for 1:10, the total of (

R10 + VR1 ) parallel

with 3M0 meter must be 1M0. Thus VR1 will be set for 500k. This

setting maybe

be kept for all meters with Rin = 3M0. The lowest meter Rin =

2M0.

For 1 : 100, set S1a+b for 1 : 100. The total of ( R12 + VR2 )

parallel with 3M0

meter must be 100k. Thus VR2 is set for 3k4.

The lowest meter Rin can be 500k for 1 : 100 ratio.

The input resistance to the R divider = 10M0. There is always

capacitance for

any probes for Vac meter or CRO, and if C = 10pF, input

impedance input of

divider begins to reduce with -3dB pole at 1.59kHz if the

circuit measured has

infinite impedance. Where the circuit has no C and R = 100k,

then 10pF gives

pole at 159kHz.

Most high Vac measurements in audio amps will involve circuit Z

> 10kHz, and

F > 200kHz, so the 10pF divider will not reduce HF very much.

For above 100kHz, and where it is possible without affecting the

circuit measured,

it is better to use an RF probe with diode and low C to convert

the high Vac to

Vdc without loading the circuit, and then you measure the peak

Vdc which is

converted to Vac by calculation.

The R divider is somewhat painful to use, but it avoids use of a

more complex and

expensive arrangement.

Measurement of Vdc should be very accurate using the divider

when VR1 and

VR2 are adjusted for the 1 : 10 or 1 : 100 ratios.

Most Vac meters have Rin at dc > 5M0.

For Vac measurement where a number of meters or CROs are to be

driven and

high bandwidth is wanted, or a Vac meter plus CRO has Cin >

100pF, an EL84

in triode cathode follower mode may be used with a stand alone

PSU of

say + 300Vdc for anode and -300Vdc for cathode resistor.

The there may be a 0.1uF coupling from R divider to EL84 grid

with grid bias

Rg 330k and bootstrapped 330k from bottom of Rk 1k4 from cathode

in series with

28k 10W to -300Vdc. Idle Idc = 10mA approx.

Heater for EL84 will be from floating 6.3V x 0.8Adc supply,

arranged from small

PT from mains with low C between mains and Vac winding.

The gain of EL84 will be 18, reduced to 0.9 in follower mode.

The effective Rin

with bootstrapped 330k is over 5M0. Cin should be less than

20pF. Noise should

be < 0.5mV, and not disturb measurements of more than 1Vrms.

Output from cathode follower is from cathode which will have Vdc

at about +14Vdc,

where Eg1 bias = 0V. There must be a 0.47uF cap from cathode

with 330k to 0V to

keep output side of 0.47uF at 0Vdc. LF pole of CF will be about

1Hz.

The VR1 and VR2 can be adjusted to be more than 1M0 and 100k

respectively so

that to obtain say 50Vrms at CF output, Vg input = 55.6Vrms,

where Vac to be

measured = 500Vrms. Thus VR1 or VR2 can compensate the CF gain

of less than 1.0.

With all reductions of Vdc or Vac input with an R divider, the

accuracy is always

challenged, despite whatever care is taken. But most technicians

do well to

measure say 97Vrms to 103Vrms where in fact there is 100Vrms.

Most measurements

of Vac are made to compare Vac at different F, and the R divider

allows the

F response to be examined at an anode powering an OPT.

Remember that where Vin = 3,000Vrms, Vac across each R1 to R9 =

300Vrms.

Current in each 1M0 = 0.3mA, and very low, so 1W metal film

ought to be OK.

But R1-R9 must be rated for 450Vdc and I suggest these be tested

with 500Vdc

for several hours before using them. Their heat will be 0.25W,

and should feel

warm. ( DON'T touch them with 500Vdc flowing ).

There are CRO probes available with 10:1 or 1:1 selectable V

ratios.

These are often better made than anything you might make and

have have 10M

input Zin so that there is 9M + 1M and the 9M is at the tip of

probe and it has low

Cin < 15pF. There is often a tiny trimmer C across 9M0 which

is adjusted for best

square wave of say 20kHz when using the probe with cable C =

67pF and CRO

Cin = 33pF, for 100pF total.

The problem with such CRO probes is their fairly low Maximum Vac

rating.

I would suggest testing circuits with 3,000V present could lead

to destroying a

meter or a CRO.

But for say 200Vrms, 10 : 1 CRO probes are very good for

observing wide

bandwidth Vac where the CRO or meter has "matching" C in of

about 33pF.

It is difficult to measure low level RF Vac at high impedance

tube circuits, eg,

at output of IFT1 at input of 455kHz IF amp grid of 6BA6 in AM

radio.

Many 455kHz IFT LC will fixed C of say 200pF, and adding say

20pF will

change Fo and lower Vo, and cause THD in detected audio F.

A cathode follower using say 1/2 6DJ8 may work well, and Vac

will be less

than 10Vrms, and Cin < 5pF if the tube is mounted at the end

of the probe to

allow short grid input wire of 30mm. It is easier to make a

small size 10 :1 R

divider with 900k + 100k and keep C r in across 100k less than

67pF, so that

C across 900k is less than 7pF. The 1M0 is high enough to

prevent reduction

of Q of LC, thus reducing Vac measured.

This website is not meant to fully explain RF phenomena or

techniques, and

best practices are part of a well trained and disciplined mind.

Lower R values for R divider may be used where circuit impedance

at DUT is

less than 10k, and if total R = 500k the Vac reduction with 500k

load is from say

100Vac to to say 98Vac, or -2%.

If measuring Va at EL34 anodes, R-divider could be 500k + 56k,

and this gives

100V : 10.7V ratio. If Vdc or Vac = 500V, current = 1mA, and OK.

If anode circuit

impedance = 5k0, then error is very low.

I often use an oscilloscope, ( aka cathode ray oscilloscope, or

CRO, ) because

it has a vacuum tube within to display wave forms without

telling lies, so you

SEE what is happening. I have a 1983 dual trace Hitachi and a

dual trace

Tektronics 465, both nice to use with reliable solid state to

drive cathode ray tube.

Bandwidth is DC to about 15MHz. But they are allergic to

excessive Vac input.

A CRO is not capable of accurate measurement, but for very many

audio

measurements the F response around various parts of a given

circuit can be

quickly recorded at +/-3dB, 6dB, 12dB. It may be compared to

response at input

with dual trace function. THD > 3% and phase shift > 5

degrees are easily seen,

all much faster than listing many Vac levels at a meter.

An old fashioned CRO with 15MHz bandwidth is better than a hand

held digital

CRO or PC with sound card etc. Cheap second hand CROs should be

plentiful.

I did not ever buy a tubed CRO because all that I found had worn

out tubes and

worn out cathode ray display tubes.

I built my first bench Vac meter in 1994 with mains PSU in small

box with SS bjt

discrete circuit with 6 ranges from 0 -10mV to 0 - 1,000V.

Bandwidth was not too

bad at -1dB at 2Hz to 200kHz, with some extending to 1MHz, but

HF response

above 200kHz was not flat. There was one amp using bjts with

gain = 100.

Input Rin was 500k to switched input R divider, and each Vac

range made to suit

the single 0.0 to 10.0 scale, so any reading below 1.0 was a

guess.

I added j-fet input after the switched R divider and some

protection. But I found to

measure Vac between 0.0 and 1.0 in the scale needed more Vac

ranges for 0.0 to

3.2 scale, and then low Vac for a 1-10 scale is seen much

better. There were passive

germanium diodes to give peak Vac, and scale was calibrated

using low THD sine

waves so that what was read was Vrms for sine waves. But a

square wave or triangle

wave gave the same peak Vac so a calculation was always needed

for Vrms for non

sine waves.

Between 2013 and 2014, I discarded the old Vac meter and totally

rebuilt the meter

according to schematics below. I retained the same old analog

meter with its 100mm

wide dial face with enough room for three scales, 0 - 10, 0 -

3.16 and a Db scale,

immensely valuable for quick response checks to about 3

significant figures.

FUTURE IMPROVEMENTS if I ever get time :-

Floating balanced input. This could be done using a 1:1 or 10:1

AF transformer at

input with a nominal input Z = 20k to secondary 20k or 6.3k.

Core saturation should

not occur with 20Vac input and below 10Hz. Such an AF

transformer needs good

shielding and primary Lp = 300H minimum, and would need mu-metal

core to reduce

distortions and it is not so easy to R&D such a thing.

Alternatively, one must build a wide band Vac meter with

re-chargeable batteries

for + / - Vdc rails. This could be difficult, but there are no

bandwidth limitations of

a transformer. The mains powered +/-Vdc rails and 0V rail may be

switched to meter

rails for single ended input with 0V tied to EARTH, so that

during most operation,

batteries are charged.

I also have a hand held DMM powered by +9Vdc from a mains plug

pack PSU

from mains. The PT is low VA, and has its secondary well

insulated from PT

primary so making floating Vac or Vdc measurements between any

two circuit

points is easy without use of batteries. It does work, but where

circuit impedance

is high, there is 50Hz interference because of the C between PT

sec and mains

winding.

To avoid this, a special single C-core mains transformer is

wound with mains

on one side of the core, and secondary on other, to reduce stray

C between

P and S. A shield over mains coil can also help reduce 50Hz

interference.

Once done, this is a very simple arrangement.

-------------------------------------------------------------------------------------------------

Vac meter 1 details.

SHEET 1. Block diagram.

SHEET 1 shows a 12 position wafer switch is used with 3

amplifiers to power

an analog meter.

The content of SHEETS 2+3+4+5 are within dashed lines......

Case = 425mm wide x 135mm high x 250mm deep, 1.6mm Aluminium,

except front

plate = 3mm thick. Heatsink for PSU regulators is aluminium

plate between PSU

and amps. The whole of SHEET 2 and SHEET 3 and the rear of the

meter itself is

encased in internal steel box to give some magnetic shielding

and ensure low noise

with amps having input impedance above 20Meg even when using the

0.0 - 1.0mVac

range.

My meter dial can be copied into your PC image program and

changed in size to

perhaps suit your meter. Most analog meters have swing of more

than 90 degrees

as mine shows.

Fig 2. Meter Dial.

I made a template using white cardboard and pencil to plot the 3

scales using my

Fluke to verify voltage measurements. The scale is substantially

linear, because

the Vdc used to drive the meter is derived from the GNFB network

of a meter amp.

For changing Vac ranges, I used an old double rotary wafer

switch with 12 terminals

for 12 positions. These old switches commonly used terminal No12

which was also

a pole which points to itself at position 12. So I could get

only 11 Vac ranges from

0 - 1mV to 0 - 100V.

The 0 - 316V is possible by having a non switched 4mm banana

socket for only

316V when the 100V Vac range is selected.

The meter is calibrated so that a pure 400Hz sine wave at

10.0Vrms gives the same

reading as my Fluke digital meter. Other readings above and

below 10V are consistent

with a good DMM.

I did consider rigging up a 2.50Vdc reference diode so peak Vac

of a Vac source

could be adjusted for 2.5peak, ie, 1.767Vrms, and the meter amp

gain adjusted so

needle sits on 1.767 Vrms on 0 - 10V scale. But the Fluke seems

to be accurate

enough, and its better to have two good meters which give the

same Vac reading,

even if they are slightly in error by up to +/- 2%.

SHEET 2. Switch details and Amp-1.

For the low Vac ranges 1mV to 100mV.

The 5 low level Vac inputs are fed from input RCA or banana

socket through 10k

bypassed with 15nF. This R&C prevents excessive input Idc

flow in limiting diodes

at Amp 1 and Amp inputs. The input blocking caps charge up

slowly.

The 10k is thus a protection measure. Once all coupling caps

charge up within

the unit there is very little delay waiting for Vac reading to

settle.

The input is fed to terminals 1a to 5a and then to input of Amp1

which has a

j-fet 2SK369 with bootstrapped bias R21, so input Z = 20Meg with

some shunt

capacitance of mainly Cg-d of 15pF with maybe 5pF of other stray

C.

For Vac ranges 1- 5, Zin = 20Meg bypassed with 20pF.

The source follower connection reduces the Cg-s from 75pF to

negligible amount.

So, any input signal will see 20Meg at 50Hz but the 20pF reduces

Zin at 6dB / octave

above 400Hz. The Zin is about 1Meg by 8kHz. For most amplifier

measurements

the Vac being measured has source resistance below 50k, thus

allowing HF -3dB

pole at 159kHz, assuming the source is not already shunted by

any additional

capacitance.

Amp 1 increases signal 10.0 times, and feeds its low Z output to

R divider R3 to R7.

Amp 2 selects signals via pole to points 1b to 5b. At each Vac

range the Amp 2 input

is a maximum of 10.0mV max for the 5 ranges.

Amp 2 increases signal 10 times to provide a maximum of 100mV to

power Amp 3.

Amp 2 input also has a bootstrapped source follower with Zin

about 15Meg bypassed

with 20pF.

Amp 3 converts the Vac to Vdc linearly to work the meter for

full swing.

Output from Amp 2 of up to 100mV can be viewed on oscilloscope.

For all input signals above 100mV, Amp1 is not used and input is

directed to each

separate R divider for each of 6 Vac ranges.

Each of these R dividers has Rin = 3.06Meg, with much less R as

the series R.

For all Vac ranges from 0.316Vac to 100Vac the Zin = 3.1Meg

bypassed with about 4pF.

There are many capacitors which need critical adjustment. C3 and

C23 are small

ceramic trim-caps set to minimize any oscillations above 1MHz.

These are very likely

if there is poor layout, inputs close to outputs, or if electro

rail caps are not bypassed

with plastic caps and if leads are not all kept extremely short.

I've used a number of

220r "gate stoppers" to prevent spurious HF above 1MHz.

Caps C9,12,14,16,18,20 are made with a 12mm length of 1mm copper

wire soldered

to switch lug with small piece of 0.5mm insulated telephone hook

up wire soldered to

other switch lug, and then wound around 1mm wire until response

from a signal gene

showed best HF extension without peaks or troughs, and a good

looking 40kHz square

wave.

Caps C11,13,17,19 were chosen after each of the others was set

for about 3 turns of

wire wrap, ie, about 4pF. Once the response looked nearly flat

and square waves had

little peaks or rounded corners the wire wrap caps were adjusted

for best flat response

and best square wave.

I was able to get all ranges from 1mV to 100V to give bandwidth

giving -1dB at 1.4Hz

to -1dB at over 250kHz with less than +/- 0.2dB change along

each band. The source

signal comes from the low impedance output from a completely

re-built 1980 BWD

function generator with F output from 0.1Hz to 2MHz.

SHEET 3. Amp-2 gain = x10.

Amp-2 is explained well within text on the schematic. You may

find this amp

could make a splendid line level audio preamp.

SHEET 4. Meter Amp-3.

The meter amp uses 4 germanium diodes in a bridge rectifier to

create a small

Idc flow to power the meter. This diode bridge and meter is

within the NFB

network with R11, R14, VR1. The total value of these three

resistors = 73r.

If you make this circuit, the R values will need to be different

to suit the meter

used.

The GNFB action makes the conversion of Vac to Vdc linear. The

FB virtually

eliminates the the non linear forward voltage turn on transfer

function of diodes.

Calibration of the meter is by applying 100mV to Amp3 input, and

turning shaft

of VR1, 300r, so that the meter has a full swing.

VR1 is a 25mm pot mounted on the board and its 6mm dia metal

shaft to a plastic

shaft with screw slot and protruding through front panel where

it is not likely to

be disturbed. Once set, the calibration has shown no sign to

drift. The NFB

eliminates all non linearity including temperature drift.

Replacement of the

meter would require the NFB resistance network values to be

revised.

C3+R5a, C8, C9 are needed to prevent HF oscillation above 5MHz.

Probably, the smart arses among you will laugh at my primitive

circuit.

And you may find ordinary op-amps would be easier, until you

realize most

do not have the ability for such wide bandwidth. It would be

nice to have

HF -1dB pole at 5MHz or higher.

But once you get to RF, measurements are difficult unless the

circuit

impedances are much lower. This Vac meter is meant for the audio

tech

needing to know about signals between DC and say 500kHz.

SHEET 5. Power Supply.

There is nothing unusual about this generic PSU. The R3,4,5,6

47r plus

bypass caps seem to fully suppress any stray coupling at any F

between

the 3 amplifiers which would cause serious stability problems.

Back to Education and DIY

directory

Back to Index page