AMPLIFIER

CHASSIS FOR SALE.

March 2015.

I have a many amplifier chassis and metalwork parts which I will

never use. They were well made by CANFAB in 2003,

http://www.canfab.com.au

The quality is equal to anything made by hi-end hi-fi amp makers

anywhere in the world.

PRICE?

If you are thinking of building a pair of monobloc tube power amps

you may email me for a price for the metalwork

AND for the freight cost to your postcode. The chassis were meant

to be used for 4 different types of of monobloc amps

which I thought I may have to supply to customers. But nobody

wanted the possible amps and they all demanded something

different or "more unique."

The parts for 22 power amp monobloc chassis have been stored under

a bench for many years.

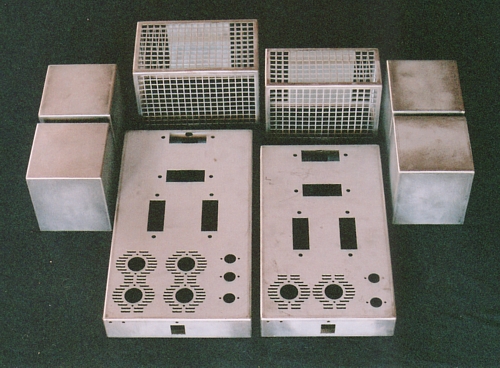

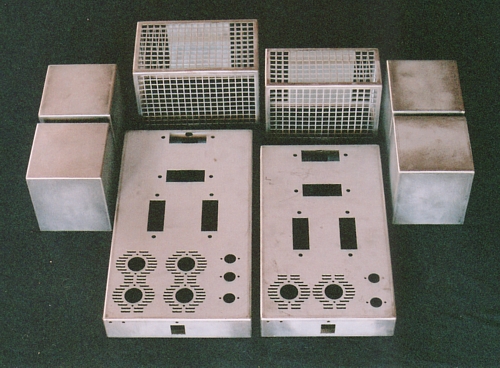

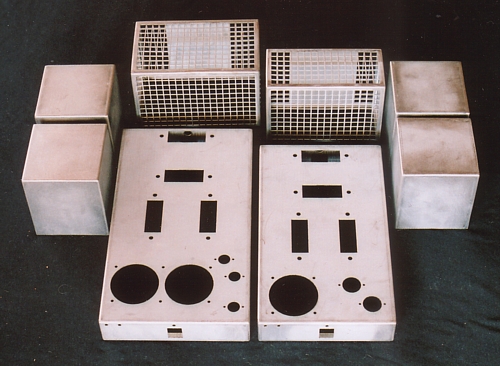

Each monobloc amp includes parts :-

1 pc main chassis with holes for tubes, ventilation.

2 pcs transformer pot,

1 pc perforated metal tube cover,

1 pc perforated metal bottom cover.

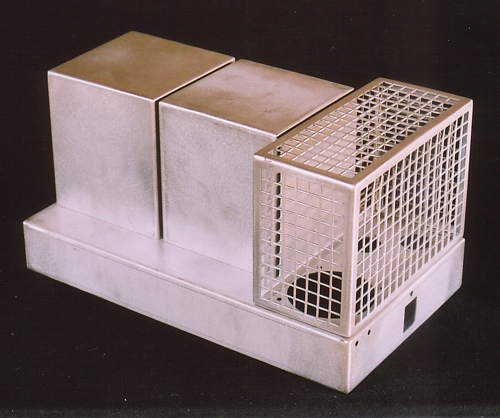

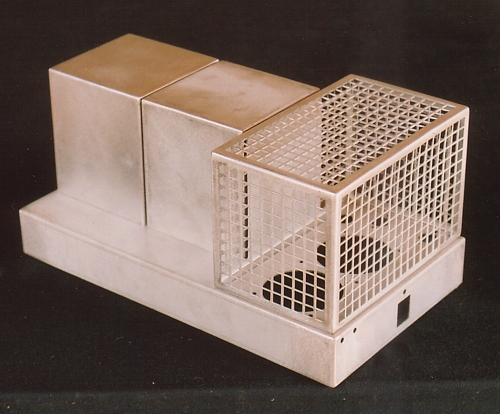

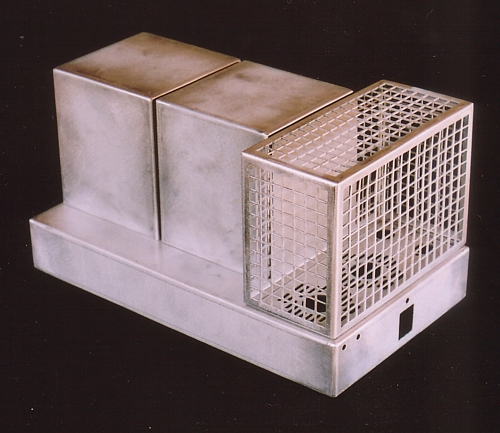

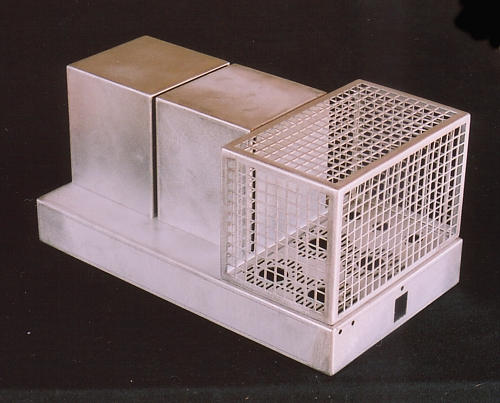

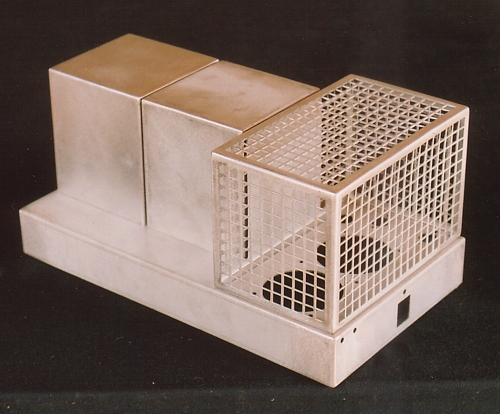

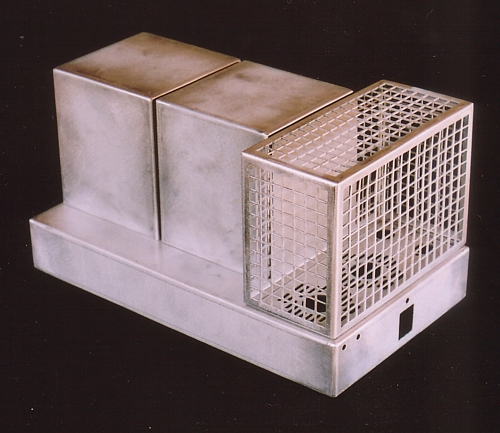

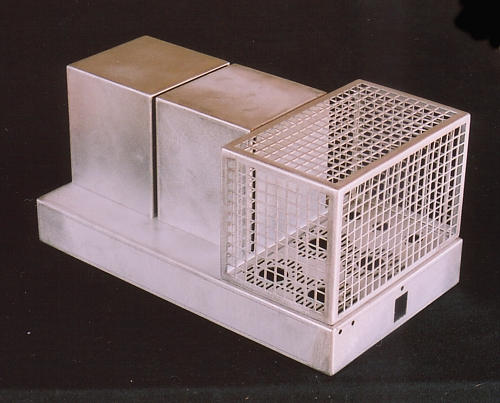

Below are some pictures of unpainted chassis ready to be filled

with parts for future amplifiers.

There are enough chassis for :-

2 monobloc SE amps, each with 1 x 13E1, 7big socket, 2

input/driver tubes.

2 monobloc SE/PP amps, each with 2 x 13E1, 7big socket. 3

input/driver tubes.

4 monobloc SE/PP amps, each with 2 x

6550/KT90KT88/EL34/6L6GC/300B.

4 monobloc SE/PP amps, each with 4 x

6550/KT90/KT88/KT120/EL34/6L6GC.

All dimensions = overall size in millimetres. To convert to inches

divide by 25.4.

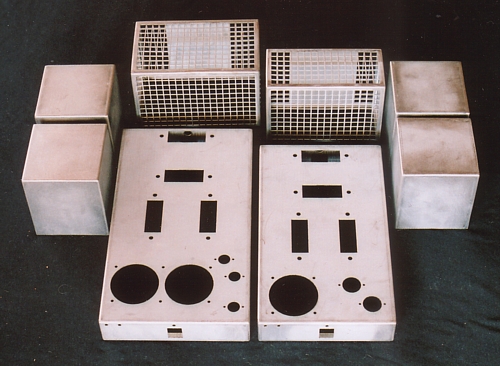

The chassis are 1.6mm thick zinc plated steel sheet.

Transformer cases and perforated cages over tubes are 1.2mm zinc

plated steel sheet. All external corners are welded

and ground smooth to give an excellent finish for powder coating.

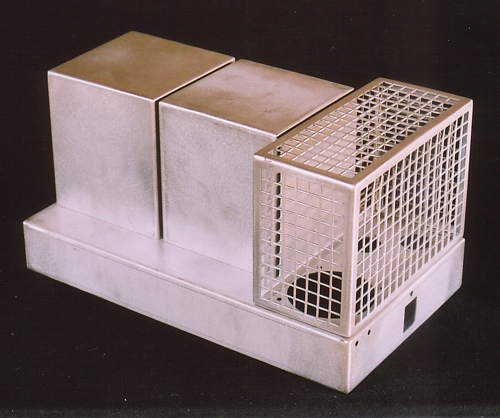

Type no 1 x 13EI.

This one is for 1 x 13EI or other single tube which may fit.

Driver and input tube = 2 x octal or 9 pin miniature tubes.

Size of chassis = 360L x 210W x 55H

Size of transformer box = 125L x 125W x 140H, allows 70S x 44T

E&I core.

Size of cage = 204L x 96W x 140H.

Type no 2x13EI.

This one is for 2 x 13EI output tubes or other such as 300B etc.

Driver tube and input = 3 x mini nine pin.

Size of chassis = 400L x 230W x 55H.

Size of transformer box = 125L x 125W x 140H, allows 70S x 44T

E&I core.

Size of cage = 224L x 136W x 140H.

Type no 2 x Octal.

This one is for 2 x Octal output tubes.

Driver tube and input = 2 x miniature nine pin, or can be enlarged

for octal.

Size of chassis = 360L x 210W x 55H.

Size of transformer box = 125L x 125W x 140H, allows 70S x 44T

E&I core.

Size of cage = 204L x 96W x 140H.

Type no 4xOctal.

This one is for 4 x Octal output tubes. Driver tube and input = 3

x mini nine pin.

Size of chassis = 400L x 230W x 55H.

Size of transformer box = 125L x 125W x 140H, allows 70S x 44T

E&I core.

Size of cage = 224L x 136W x 140H.

Typical details of chassis cut-outs :-

2 x Octal, 4 and 2 x Octal chassis :-

The large slots where transformers are mounted allow for the

primary and secondary terminals to be

mounted in fibreglass boards to project into the sub-chassis area

for easy wiring to tubes and for easy strapping

of secondary windings to suit different speaker loads.

The E&I laminations are vertically mounted and the clamp yokes

bolt to the chassis through each hole near each

end of the the chassis slots. The laminations are kept slightly

clear of the steel sheet chassis material.

Slots around the octal socket holes allow for cooling air flow up

around each output tube but not allowing objects

less than 3mm dimension to fall through the slots.

Not shown are the 2mm steel plate transformer yokes and steel

bottom plates with a large area perforated for ventilation.

1 and 2 x 13EI chassis :-

The large slots where transformers are mounted allow for the

primary and secondary terminals to be mounted

in fibreglass boards to project into the sub-chassis area for easy

wiring to tubes and for easy strapping of

secondary windings to suit different speaker loads.

The E&I laminations are vertically mounted and the clamp yokes

bolt to the chassis through each hole near

each end of the the chassis slots. The laminations are kept

slightly clear of the steel sheet chassis material.

The large 75mm dia holes for output tubes allow for small metal

plate about 80mm x 80mm to be mounted

say 25mm below the chassis top and which has a hole suitable hold

a 7big socket for 13E1, or other large

output tube, perhaps 6C33C, GM70, or KT120/150.

The small sub-chassis plate allows a generous air flow up around a

large output tube.

Not shown are the 2mm steel plate transformer yokes, steel bottom

plates with a large area perforated for ventilation

and sub-chassis plates for mounting 13E1 sockets.

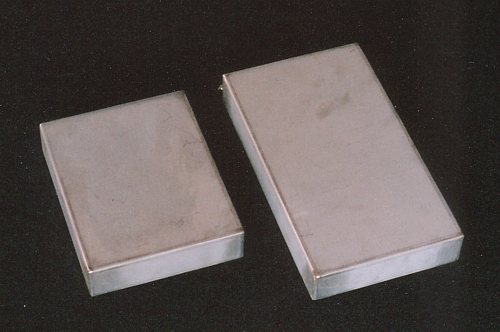

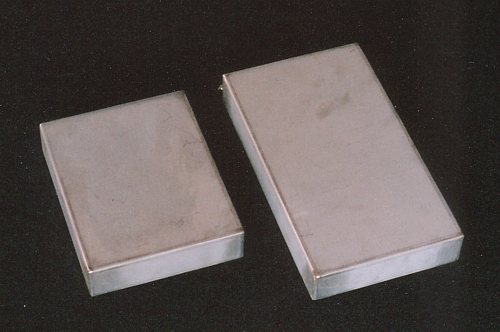

Chassis for preamps.

The preamp chassis are without any holes.

A small number are available.

The all-steel metalwork would need a considerable number of

additional holes to be drilled tapped for M3

or M4 c/s machine screws. For mass production, powder coating is

normally done to multiple chassis

after ALL holes and threads have been cut and all hole edges have

been de-burred and all oil cleaned off,

and surfaces sanded again by hand.

But for DIYers who want to make only 2 amps, they may have chassis

powder coated before the

additional holes and threads are cut. This involves more care with

c/s holes.

Painted or powder coated chassis should be covered in 2+ layers of

masking tape during assembly and work

on bench.

Mistakes with hole positions or hole sizes or blemishes cannot

easily be repaired.

Radical changes to design as you progress cannot be accommodated.

DIY hobbyists will make terrible mistakes

because of their lack of experience. I was a very patient and

thoughtful craftsman who took time to set out the hole

drilling so that the prototype amps I made became the finished amp

which I sold. The chassis have room for any

typical amp schematic I have at this website. The chassis were not

powder coated by CANFAB because not

everyone wanted black amps. Well done powder coating is cheaper

and harder than any automotive spray paint

or applied by asian amp makers. While chrome plating is possible,

I don't like it. Seeing samples of old chrome

plated amplifiers ( EAR509 ) led me to believe chrome is prone to

peeling, cracking and blemishes.

Back to Index Page